If it was not obvious, we took a wee little break from kitchen reno to have a think (and a drink). As sometimes happens, we need to get away from the day-to-day conundrum when we find ourselves paralyzed with indecision and downright panic!

What had us in delay-delay-delay mode were two issues: the open shelving disaster/dilemma and how to finish out a very nook-and-crannyish massive island (11 ft by 8.5 ft), so we did what all good DIY-ers do. We took a break and worked on something else.

Not for nothing, but long walks with the newest edition to our family, via our son, our beloved grand-pup, Teague, will cure whatever ails ya.

First, though, a quick overview of where things took a turn on the freaking shelving front.

You’ll see in the photos below, the (VERY) hard walnut wood shelves are show-stopping gorgeous. But, the system that we chose, after exhaustive research (and reading every review possible), was causing problems for us and our gloriously new stacked tile wall.

The idea for these shelves was to drill holes in the back of them at the exact point where the protruding posts are, using the jig that the company sold us to make it easy. When all is said and done, the shelves would “seamlessly” slide onto the posts.

That did not happen.

We may not be the sharpest knives in the drawer, but we knew enough to practice on dummy shelving first. We know the posts are level, from one post to another, and even along their length, from front to back — dead level. Where we are running into a problem is that each one is angled ever-so-slightly to the left or right and that causes problems when one has drilled a straight, 90 degree hole.

The obvious choice is to drill the holes larger, to accommodate any annoying angles. We are going to try that before we move on to Plan D (or is it E — who knows, at this point?!) We also have purchased enough large-scale drills to build a small skyscraper.

After many late night conversations, tape measure pulls, and being attached to our level like it is an appendage, we have tabled the decision-making, for now. The shelves sitting on top of the posts provide the necessary storage to get on with our day, even if it also provides a bird’s eye view into how the open-shelving sausage is made.

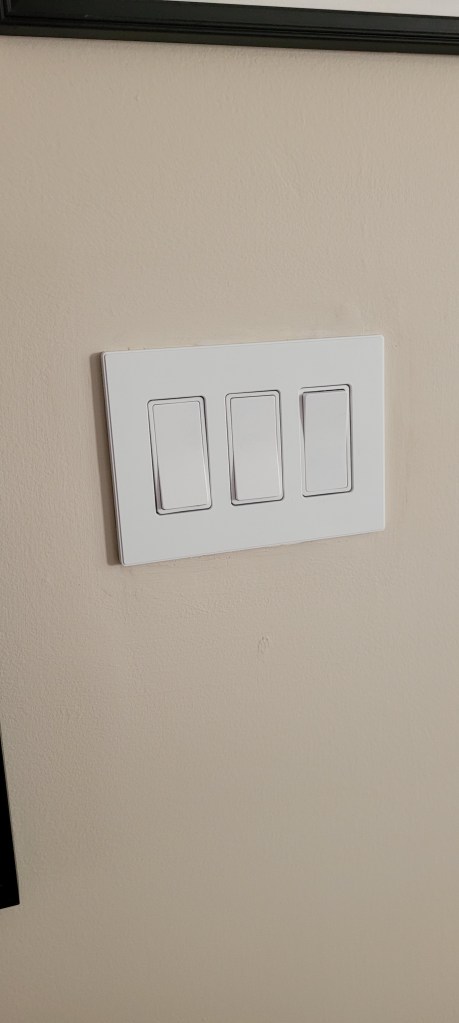

Instead, we finished lots of caulking and we switched out all of our outlet and light switch covers to these nifty screwless rockers for a nice clean look. Screw-in outlets are so 2022, after all 🙂 We also installed an Alexa-enabled switch for our over-head pocket lighting, so we don’t have to walk around the entire island to turn the lights off or on. A major upgrade for us.

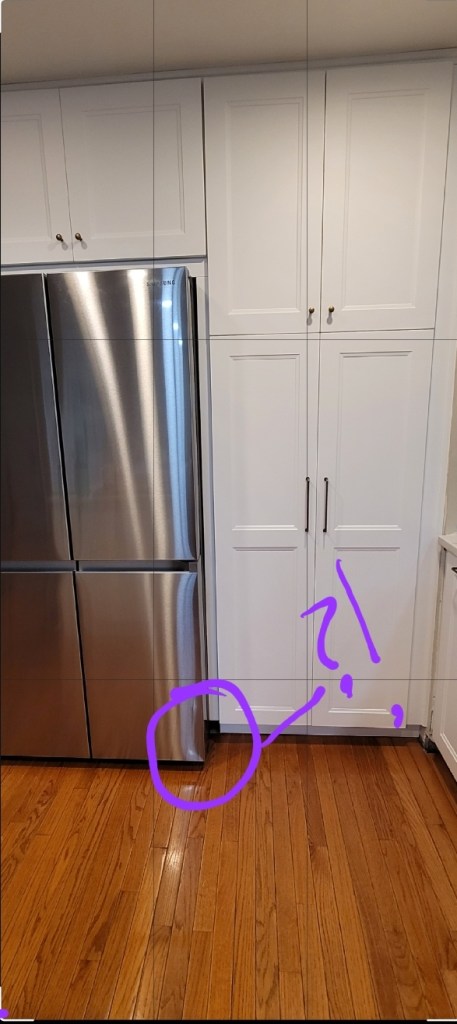

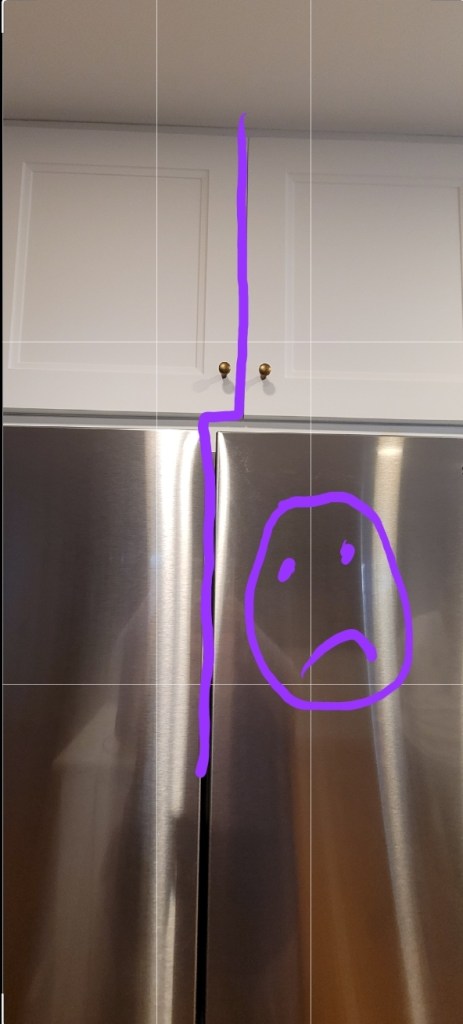

We also finished out all the base moulding in the kitchen and island. That is an easy, but time-consuming task, so glad to have it behind us.

Eagle eyes will be able to see how we resolved the island trim issues in the photo above (and, if you are really on top of things, the title of this post might have given you a clue, too!)

We had always assumed we would do box trim on the island. But, there are so many bump-outs and angles that it was becoming waaaaay too busy and psychedelic for our taste. Instead, we opted for…you guessed it…a much simpler hybrid board-and-batten trim that looks way better than the box trim. Less fussy, more in keeping with the clean style of the kitchen and dining room, and the rest of the house, as well.

So, this week, we are priming everything and then we’ll get to painting the island and finishing up the toe kick on all the trim. And with that, the entire island will be FINISHED.

Following that mini-milestone, we go on holiday for a week. Anything to get out of making some decisions on those stinkin’ shelves, I tell ya.